Productive Process

Sealand Aquaculture produces the smolts in land-based facilities using recirculation technologies for water treatment. With innovation constantly taking place, new and different technologies have been introduced to limit the environmental impact to an absolute minimum.

98% of the water is treated and reutilized in the production processes. The introduction of reverse osmosis has further optimized the use of the water.

Another key development has been the direct loading of fish from the tanks to the well-boats. Compared to the usage of trucks the fish are significantly less stressed, transport times and costs are reduced which dramatically limits the CO2 footprint.

Productivity has improved overall, survival rates from egg to smolt are over 65% with an average smolt weight of 180 grams. The smolts are delivered at 400 grams and fully adapted to seawater environments.

The production volume has been expanded to 16,800 m2 and the production capacity has increased to over 2,100 tons annually.

From egg certification to post-smolt

The production process is divided into 5 phases, starting with the reception of the eyed eggs, and ending with the transportation of the smolts to the sea sites. All stages of the production process are tightly controlled and monitored constantly.

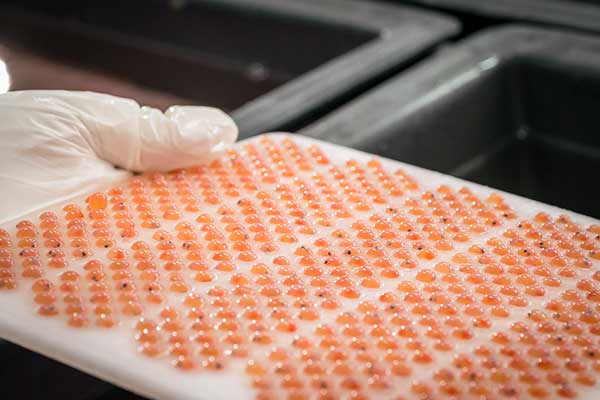

1. EGG RECEPTION

Strict quality control of the eggs takes place before the eggs enter the facility. Broodstock is individually screened, eggs of non-complying broodstock are eliminated. Only certified pathogen-free eggs are used in the production process.

2. INCUBATION

Eyed eggs are received in the hatchery where they are incubated at optimal temperature. After hatching and yolk sac absorption the fingerlings are transferred to ‘first feeding’.

3. FIRST FEEDING

The yolk sac is absorbed and the fingerlings start to eat a specially formulated diet for early-stage development. A first selection takes place.

4. PRE-SMOLT

Reaching a weight of 2 grams after 8 weeks the fingerlings are transferred to the next unit, ‘fingerling’. The fish are kept for 8 weeks until they reach 50 grams. At 20 grams the fish are graded and distributed in subgroups.

5. SMOLTIFICATION

Smoltification is the physiological adaptation process of the fish changing so they are able to flourish in a seawater environment. The process is triggered by adapting to the day night rhythm, the so-called photoperiod. At this stage the fish are vaccinated to protect them for diseases at sea. When the fish are fully smoltified and the desired weight is achieved the smolts are transferred to the sea sites.

Biosecurity

Sealand Aquaculture ensures full compliance with all biosecurity protocols including, among others, in the following areas:

– Full separation of all processes between the various epidemiological units, groups of fishes with the same exposure to infections.

– Certification of all sanitary processes for eggs entering the facility such as the spawning of broodstock and the screening of eggs.

– Complete disinfection of all production systems at regular intervals certified by external audits.

– Disinfection of the effluent water.

– Full control of all movements at the farm, people, vehicles, boats, equipment, feed and others.

– Constant monitoring of fish health and disposal of mortality.

– Control of all vectors of disease transmission.

Indicators

2.400

tons anual production capacity

200

millions of incubated eggs

130

millions of produced smolts

600.000

tons of final harvest volume at sea

Certifications

Epidemiological Unit

In 2011, Sernapesca established a sanitary program for the surveillance and control of ISA (Infectious Salmon Anemia). An Epidemiological Unit (EU) is a group of fish in a separate section of a fish farm with the same risk to be exposed to the virus.

From the start in 2011, Sealand Aquaculture’s fish farms have been recognized as separate Epidemiological Units.

BPL (Good Labor Practices)

In 2013, Sealand was awarded with Outstanding Compliance of the BPL program by the Ministry of Labor. The program includes compliance with general labor practices as well as health and safety procedures.

Best Aquaculture Practices (BAP)

In January 2016 Global Aquaculture Alliance (GAA) awarded Sealand Aquaculture the global Best Aquaculture Practices (BAP) certification. The Global Aquaculture Alliance (GAA) is an industry organization that promotes responsible practices in the aquaculture industry.

BAP is an international certification system audited by independent third parties, verifying key elements of responsible aquaculture, including elements like environmental responsibility, social responsibility, food safety, health, animal welfare and traceability. The BAP standards cover the entire aquaculture value chain, from hatcheries to fish farms including processing plants and feed factories.